Get to know

Our Manifest

A company concerned about the future is one that generates a positive impact for people and the planet. Naturally, in the essence of the business. A sustainable company is one that is able to generate profit with a positive impact on businesses.

Sustainability is part of our essence. We promote a true circular economy with an integrated end-to-end production process: from raw material production to products, which return to the production chain after use.

Thoughtfully and carefully, we develop products and services with absolute respect for people and the environment. And we seek to adopt practices for the preservation of nature and the social well-being of the nearby communities.

Committed to the constant seek for positive innovations, we deliver to society a robust portfolio of products and services that are essential to everyday life.

After all, transforming people’s lives with sustainable attitudes and solutions is our purpose.

Positive impact solutions

Papers for Sustainable Packaging

Our seven lines of papers for sustainable packaging have grammages from 30 to 200 g/m² and they contribute to us being the third largest producer of papers for sustainable packaging in Brazil.

We are a national reference in the production of paper for delivery bags. The BagKraft line has three exclusive Irani variations: Prime, Smart and Cycle.

Our lines of paper FineKraft, FlexiKraft, FlashKraft and FlatKraft are certified for use in contact with food. With exclusive Irani’s recipes, they are produced with virgin fiber from our planted forests.

Contact our team to know the ideal type of paper for your needs:

Aline Oliveira

Commercial Department

+55 (19) 2107-7151

+55 (11) 95021-6670

alineoliveira@irani.com.br

Sustainable Corrugated Cardboard Packaging

Our sustainables corrugated cardboards packaging are designed to meet the needs of each customer in different segments. They are produced with recycled raw material and they are 100% recyclable.

We develop customized packaging, designed exclusively for each purpose, such as e-commerce.

Our sustainable packaging guarantees high efficiency and safety for the products’ transportation.

Segments served:

- Miscellaneous products

- Clothing and footwear

- Pharmaceuticals and cosmetics

- Chemicals and derivatives

- Hortifruti and floriculture

- Food products

- Meat products

- Dairy products

Sustainable Corrugated Cardboard Sheets

We offer sustainable corrugated cardboard sheets on different compositions, manufactured in single or double walls with grammages from 330 to 1440 g/m².

We produce sustainable sheets in recycled, kraft or white paper, in waves B, C, D, E and BB, BC, BE that guarantee high strength and great performance in converting and printing.

Our sustainable corrugated cardboard sheets can be converted into various items such as boxes for different uses, toys and accessories.

Types:

- Recycled

- Kraft

- White

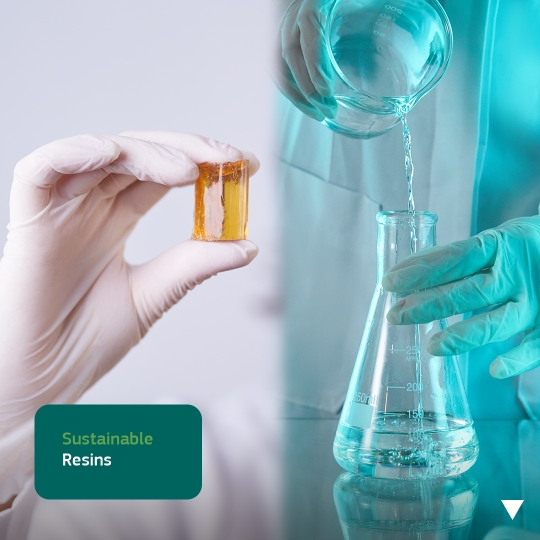

Sustainable Resins

We produce gum rosin and turpentine, sustainable pine resins that have great versatility of application in products such as varnishes, paints, adhesives and enamels.

We extract resin from our planted pine forests, managed in an ecologically correct, socially fair and economically viable way.

Our sustainable resins are indicated for the production of several products around the world. 96% of production is exported.

Types:

Gum Rosin

Technical Guide – Gum Rosin (pdf)Turpentine

Technical Guide – Turpentine (pdf) Product Summary (pdf) Our Production(pdf)Contact our team to know the ideal type of paper for your needs:

Aline Oliveira

Commercial Department

+55 (19) 2107-7151

+55 (11) 95021-6670

alineoliveira@irani.com.br

Special Solutions

We develop special, sustainable and differentiated solutions that are essential to everyday life.

Our special solutions are developed by teams focused on seeking innovations in products and services.

With pioneering and innovative spirit, we were the first Brazilian industry to launch a product line with antimicrobial protection.

Solutions:

Antimicrobial LineCustomized Services

We offer focus of the client services to generate prosperity, looking at the same scenario as the companies we work with and seeking to anticipate their needs.

We always seek to expand our prosperity cycle, by sharing knowledge through training to our clients.

Our packaging specialists and Research and Development teams create, side by side with our clients, the best custom solution for each business.